CNC Machining

SOMI Capability

SOMI CNC Machining Capability

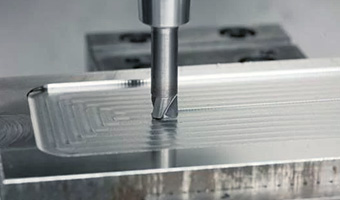

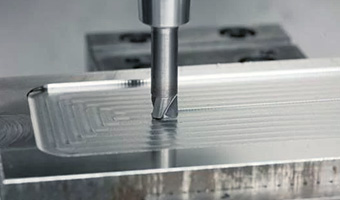

3,4,5 Axis CNC Milling

We have different types of CNC milling centers, including 3-axis, 4-axis and 5-axis milling centers. Custom parts from simple to complex structures, metal or plastic materials, can be solved.

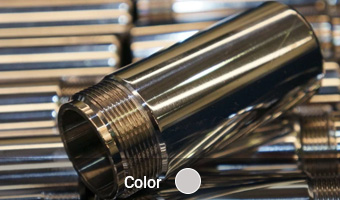

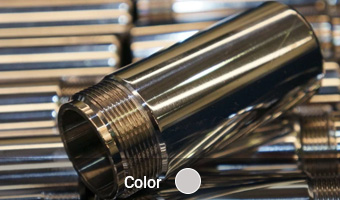

CNC Turning

SOMI uses CNC lathes and turning centers (including local brand or imported brand machines) to process metal parts, mainly focusing on cylindrical parts. Ensure components achieve consistent size and finish.

CNC Machining

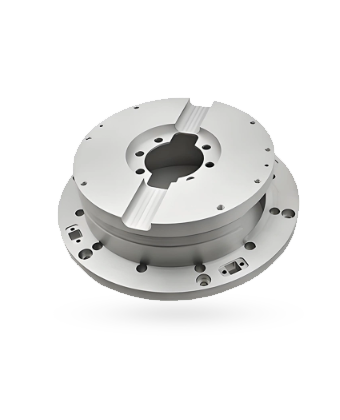

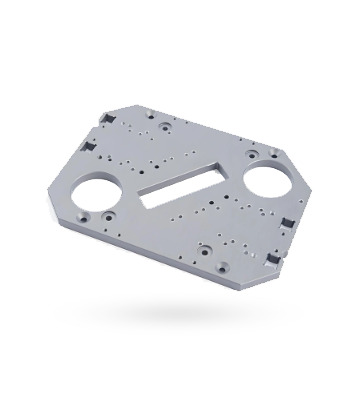

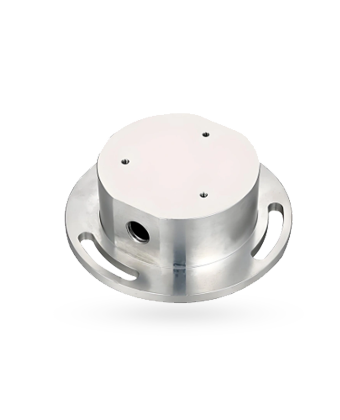

Show Custom Parts Machined by SOMI

CNC Machining

CNC Machining Materials

We offer a wide selection of materials for custom parts to complete prototypes and production runs of custom parts. The materials we process are very broad and include metals, plastics, and some composites. Metal

Metal

- Aluminum

Aluminum has a good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. It is a highly malleable metal, making it easy to machining, can be anodized.

Type:1050,1060,2011,2024,5052,5051, 6061, 6063, 7075,7050

- Brass

Aluminum has a good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. It is a highly malleable metal, making it easy to machining, can be anodized.

Type:1050,1060,2011,2024,5052,5051, 6061, 6063, 7075,7050

- Stainless steel

Aluminum has a good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. It is a highly malleable metal, making it easy to machining, can be anodized.

Type:1050,1060,2011,2024,5052,5051, 6061, 6063, 7075,7050

- Copper

Aluminum has a good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. It is a highly malleable metal, making it easy to machining, can be anodized.

Type:1050,1060,2011,2024,5052,5051, 6061, 6063, 7075,7050

- Mild Steel

Aluminum has a good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. It is a highly malleable metal, making it easy to machining, can be anodized.

Type:1050,1060,2011,2024,5052,5051, 6061, 6063, 7075,7050

- Beryllium bronze

Aluminum has a good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. It is a highly malleable metal, making it easy to machining, can be anodized.

Type:1050,1060,2011,2024,5052,5051, 6061, 6063, 7075,7050

- Alloy steel

Aluminum has a good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. It is a highly malleable metal, making it easy to machining, can be anodized.

Type:1050,1060,2011,2024,5052,5051, 6061, 6063, 7075,7050

- Titanium

Aluminum has a good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. It is a highly malleable metal, making it easy to machining, can be anodized.

Type:1050,1060,2011,2024,5052,5051, 6061, 6063, 7075,7050

- Tool steel

Aluminum has a good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. It is a highly malleable metal, making it easy to machining, can be anodized.

Type:1050,1060,2011,2024,5052,5051, 6061, 6063, 7075,7050

Plastic

Plastic

- ABS

It is a thermoplastic polymer material with high strength, good toughness, corrosion resistance, high temperature resistance.

- PVC

It is a thermoplastic polymer material with high strength, good toughness, corrosion resistance, high temperature resistance.

- POM

It is a thermoplastic polymer material with high strength, good toughness, corrosion resistance, high temperature resistance.

- Polypropylene(PP)

It is a thermoplastic polymer material with high strength, good toughness, corrosion resistance, high temperature resistance.

- Nylon

It is a thermoplastic polymer material with high strength, good toughness, corrosion resistance, high temperature resistance.

- PET

It is a thermoplastic polymer material with high strength, good toughness, corrosion resistance, high temperature resistance.

- PTFE(Teflon)

It is a thermoplastic polymer material with high strength, good toughness, corrosion resistance, high temperature resistance.

- FR-4

It is a thermoplastic polymer material with high strength, good toughness, corrosion resistance, high temperature resistance.

- Polycarbonate(PC)

It is a thermoplastic polymer material with high strength, good toughness, corrosion resistance, high temperature resistance.

- PMMA

It is a thermoplastic polymer material with high strength, good toughness, corrosion resistance, high temperature resistance.

- Polyethylene(PE)

It is a thermoplastic polymer material with high strength, good toughness, corrosion resistance, high temperature resistance.

- PEEK

It is a thermoplastic polymer material with high strength, good toughness, corrosion resistance, high temperature resistance.

CNC Machining

CNC Machining Surface Finishes

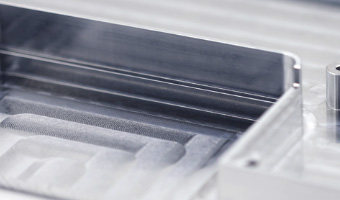

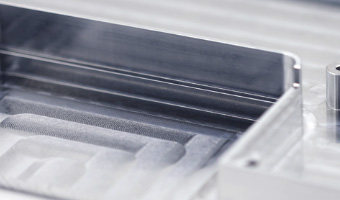

As-machined

The standard finish of our parts, the "machined" finish, has a surface roughness of 3.2 μm (126 μin), which removes sharp edges and cleanly removes burrs from the part.

Machining Texture:There are slight scratches on the visible surface.

Smooth machining

A finishing CNC machining operation can be applied to the part to reduce its surface roughness. The standard smoothing surface roughness is Ra 1.6 μm (64 μin). Light surface scratches are visible.

Machining Texture:Visible, light surface scratches.

Fine machining

Refers to the process of precision treatment of raw materials or semi-finished products. The standard smoothing surface roughness is Ra 0.8 μm (32 μin).

Machining Texture:Slightly visible.

Bead blasting

Bead blasting refers to the use of round spherical media that, when impacted against the surface of a part, will leave a more uniform finish caused by the sphere “dimpling” the surface.

Machining Texture:Frosted grain.

Brushing

Brushing is a surface treatment process that uses abrasive belts to draw traces on the surface of a material, usually for aesthetic purposes.

Polishing

From Ra 0.8 to Ra0.1, the polishing process uses abrasive materials to rub the surface of the part, making the surface of the part more shiny, depending on your requirements.

Machining Texture:Smooth, glossy finish

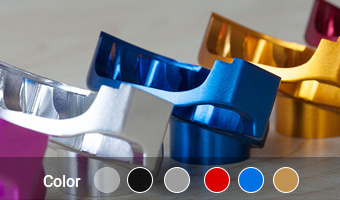

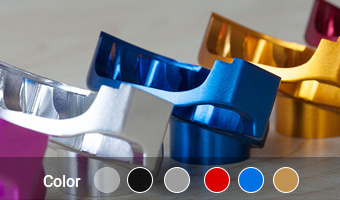

Anodizing

Aluminum and its alloy in the corresponding electrolyte and specific process conditions, due to the action of external current, the process of forming an oxide film on the aluminum product.

Machining Texture:Smooth, matte finish.

Electroplating

Electroplated coating preserves the surface of parts and resists rusts and other defects from causing decay by applying electric currents to reduce metal cations.

Machining Texture:Smooth, glossy finish.

Electroless nickel plating

Electroless nickel plating is a process that deposits an alloy of nickel-phosphorus onto the surface of a metal. This process is chemical only, so does not involve the use of electricity.

Machining Texture:Reduced but visible.

Black oxide

Black oxide is a conversion coating similar to Alodine that is used for steel and stainless steel. It is used mainly for appearance and for mild corrosion resistance..

Machining Texture:Smooth, matte.

Powder coating

Using corona discharge, we make the powder coating adsorbed to the part, creating a more wear-resistant layer with a typical thickness ranging from 50 μm up to 150 μm.

Machining Texture:Glossy.

Chromate conversion coating

Chromate conversion coating is a type of conversion coating, used on aluminum as a corrosion inhibitor, as a primer for paint due to increased adherence or to preserve electrical conductivity.

Machining Texture:Visible.

Electrophoresis

In the solution under the action of direct current electric field, the charged resin moves to the opposite electrode phenomenon. Strong corrosion resistance, can be on different colors.

Machining Texture:Visible.

As-machined

The standard finish of our parts, the "machined" finish, has a surface roughness of 3.2 μm (126 μin), which removes sharp edges and cleanly removes burrs from the part.

Machining Texture:There are slight scratches on the visible surface.

Smooth machining

A finishing CNC machining operation can be applied to the part to reduce its surface roughness. The standard smoothing surface roughness is Ra 1.6 μm (64 μin). Light surface scratches are visible.

Machining Texture:Visible, light surface scratches.

Fine machining

Refers to the process of precision treatment of raw materials or semi-finished products. The standard smoothing surface roughness is Ra 0.8 μm (32 μin).

Machining Texture:Slightly visible.

Bead blasting

Bead blasting refers to the use of round spherical media that, when impacted against the surface of a part, will leave a more uniform finish caused by the sphere “dimpling” the surface.

Machining Texture:Frosted grain.

Brushing

Brushing is a surface treatment process that uses abrasive belts to draw traces on the surface of a material, usually for aesthetic purposes.

Polishing

From Ra 0.8 to Ra0.1, the polishing process uses abrasive materials to rub the surface of the part, making the surface of the part more shiny, depending on your requirements.

Machining Texture:Smooth, glossy finish

Anodizing

Aluminum and its alloy in the corresponding electrolyte and specific process conditions, due to the action of external current, the process of forming an oxide film on the aluminum product.

Machining Texture:Smooth, matte finish.

Electroplating

Electroplated coating preserves the surface of parts and resists rusts and other defects from causing decay by applying electric currents to reduce metal cations.

Machining Texture:Smooth, glossy finish.

Electroless nickel plating

Electroless nickel plating is a process that deposits an alloy of nickel-phosphorus onto the surface of a metal. This process is chemical only, so does not involve the use of electricity.

Machining Texture:Reduced but visible.

Black oxide

Black oxide is a conversion coating similar to Alodine that is used for steel and stainless steel. It is used mainly for appearance and for mild corrosion resistance..

Machining Texture:Smooth, matte.

Powder coating

Using corona discharge, we make the powder coating adsorbed to the part, creating a more wear-resistant layer with a typical thickness ranging from 50 μm up to 150 μm.

Machining Texture:Glossy.

Chromate conversion coating

Chromate conversion coating is a type of conversion coating, used on aluminum as a corrosion inhibitor, as a primer for paint due to increased adherence or to preserve electrical conductivity.

Machining Texture:Visible.

Electrophoresis

In the solution under the action of direct current electric field, the charged resin moves to the opposite electrode phenomenon. Strong corrosion resistance, can be on different colors.

Machining Texture:Visible.

Industry

Application Areas of CNC Machining

Consumer Electronics

Our manufactured electronic components consistently meet the tight tolerances required in this ever-evolving industry.

Learn More

Aerospace & Aviation

Our manufactured electronic components consistently meet the tight tolerances required in this ever-evolving industry.

Learn More

Automotive

Our manufactured electronic components consistently meet the tight tolerances required in this ever-evolving industry.

Learn More

Medical

Our manufactured electronic components consistently meet the tight tolerances required in this ever-evolving industry.

Learn More

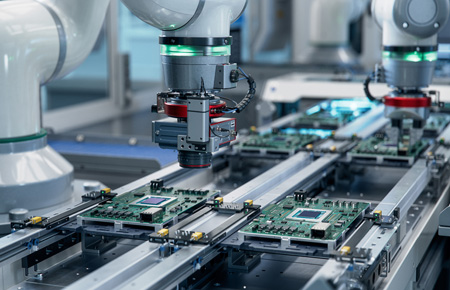

Robotics & Automation

Our manufactured electronic components consistently meet the tight tolerances required in this ever-evolving industry.

Learn More

Industrial Machinery Parts

Our manufactured electronic components consistently meet the tight tolerances required in this ever-evolving industry.

Learn MoreTest Inspection

Quality Assurance at the Heart of Our Operations

Get a Quote

Contact us Today for Your CNC Machining Requirements

Ready to elevate your manufacturing with the precision and quality of SOMI's CNC machining services? Contact us today to discuss your project and discover how we can help you achieve unparalleled results. With SOMI, you're not just choosing a service provider, you're choosing a partner dedicated to your success.

We hope to discuss potential cooperation opportunities with you and ask you to provide quotation information for your project. Looking forward to your reply and working with you to promote the success of your project!

- *Name

- *Tel

- *Title

- *Content

FAQ

Frequently Asked Questions

- Q: What determines the cost of CNC machined parts?Material: The type and quality of the material used can significantly impact the cost. Some materials are more expensive or more challenging to machine than others.Complexity of Design: More intricate and complex designs require more time and specialized tools, increasing the cost.Production Volume: Higher volumes can reduce the cost per unit due to economies of scale, while low-volume or prototype runs may be more expensive.Machining Time: The longer it takes to machine a part, the higher the cost. This includes factors like the number of operations required and the speed at which the material can be removed.Finishing and Tolerances: Additional processes like finishing, surface treatment, or achieving tight tolerances can add to the overall cost.Setup and Tooling: Initial setup, custom tooling, and programming costs can also affect pricing, particularly for smaller production runs.Labor and Overhead: The cost of skilled labor and the operational overhead of the manufacturing facility can also influence the final price.

- Q: What kind of equipment do you have available?A: We have a wide range of high-precision CNC machining equipment, including CNC lathes, milling machines, grinders, and multi-axis machining centers. This allows us to handle various materials and produce complex, detailed parts with consistent accuracy. Our equipment is designed to meet the needs of industries such as automotive, aerospace, medical, and more.

- Q: What is CNC machining?A: CNC machining (Computer Numerical Control machining) is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This technology controls a range of complex machinery, such as grinders, lathes, and milling machines, to create parts or products from various materials. CNC machining is highly precise, allowing for the production of complex shapes and detailed parts with consistent accuracy.