Your Source for Custom Medical Device Parts

- Your Trusted Partner From Rapid Prototyping to mass production

- Numerous machining networks, a wide selection of materials and finishes

- Perfect order tracking and product quality management

Industry Solutions

Precision Components for Enhanced Medical Device Performance

Customized Metal Components for Medical Devices by SOMI: High-Precision Solutions for Critical Applications

SOMI Custom Parts can offer a variety of high-precision metal component manufacturing services for medical device production. Below are specific examples:

- Surgical Instrument Components

- Diagnostic Imaging Equipment Parts

- Laboratory Analytical Instrument Components

- Rehabilitation Device Components

- Medical Rails and Sliders

- Sensor Housings and Mounting Brackets

- Pump Bodies and Valves

- Custom Connectors and Fasteners

- Internal Support Structures for Medical Devices

SOMI Manufacture

SOMI Manufacturing Capabilities of Medical Devices

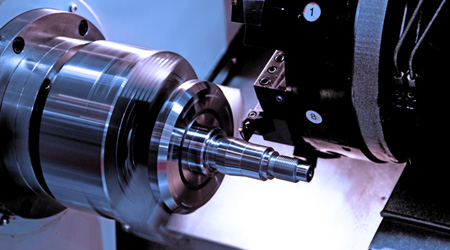

CNC Machining

CNC machining and automated processes that produce precision, complex aluminum CNC machined parts with high dimensional tolerances.

Learn More

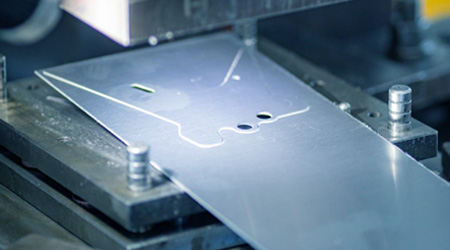

Sheet Metal Fabrication

Laser cutting, plasma cutting, water jet cutting, and bending. Six materials including aluminum, stainless steel, and brass.

Learn More

Injection Molding

Injection molding for plastic parts with intricate geometries, using a range of thermoplastics and thermosetting plastics.

Learn More

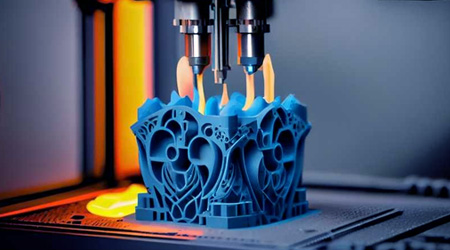

3D Printing

Additive technologies include metal 3D printing, SLA, SLS, FDM, and more. 30 plastic and metal materials in a range of finishes.

Learn More

Die Casting

High-pressure die casting for aluminum, zinc, and magnesium alloys, ensuring excellent surface finish and stability.

Learn More

Stamping

High-speed metal stamping for complex parts. Includes progressive die stamping and deep drawing.

Learn MoreMaterials and Process

Materials and Surface Finishes for Custom Medical Device Parts

Materials for Medical Devices Parts

We machine metals like Aluminum, Steel (Stainless, Mild, Alloy, Tool), Brass, Copper, Beryllium Bronze, and Titanium. For plastics, we work with ABS, POM, Nylon, PTFE (Teflon), PC, PE, PVC, PP, PET, FR-4, PMMA, and PEEK.

Learn More

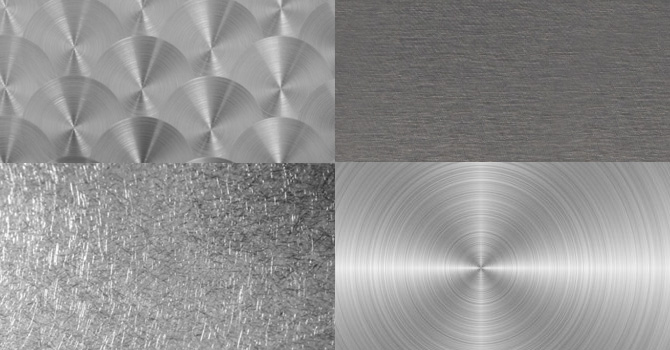

Surface Finishes for Medical Devices Parts

We offer various surface finishing processes, including anodizing, plating, powder coating, painting, polishing, sandblasting, and heat treatment, to enhance durability, appearance, and corrosion resistance of metal and plastic parts.

Learn MoreCustomized Products

Custom Medical Device Parts Gallery

Cases

Success Stories

3D printed mouse for easy customization

We are a startup, and working with SOMI has allowed us to quickly and easily implement the latest personalized mouse, and the results are amazing.

Learn More

Game controller customization

We are a startup, and working with SOMI has allowed us to quickly and easily implement the latest personalized mouse, and the results are amazing.

Learn More

Iron Parts Products

We are a startup, and working with SOMI has allowed us to quickly and easily implement the latest personalized mouse, and the results are amazing.

Learn MoreAdvantages

How Does SOMI Help You Achieve Your Custom Part Needs and Grow?

Certification of SOMI Manufacturing Network Supplier

SOMI suppliers have certification, such as ISO:9001, ISO:13485, AS:9100, ATF16949 or any other industry-specific certifications

Certification CenterHighest Quality Standards

SOMI's manufacturing network adheres to ISO9001 standards. We enforce strict quality controls from raw material inspection to final product testing, ensuring on-time delivery and minimal disputes.

Material Test ReportManufacturing Capacity (Innovative Development)

The SOMI manufacturing network has a wide range of manufacturing capabilities, with more than 300+ partners, advanced equipment and a strong engineering team to provide solutions for different customer needs

ManufacturingPrice Advantage

According to the needs of our customers, we choose the right process manufacturing suppliers in the SOMI manufacturing network to ensure that we can provide customers with products that meet the quality standards and at a reasonable price.

Quick QuoteIP Protection

SOMI will protect the confidentiality of all data files uploaded by customers. We can also sign a confidentiality agreement if the customer needs it.

Contact Us1 Piece Customized Acceptable

At the beginning of every project, the design of the product is uncertain, and we understand this need of our customers, so in addition to bulk orders, we also accept small batch orders, and even one piece customized Acceptable

Start CustomizingGet a Quick Quote

Get Quick Quotes for Your Custom Part Requirements

SOMI Manufacture Capabilities

Customized Quick Service Quote

- Service Request Quote

- *Name

- *Tel

FAQ

Frequently Asked Questions

- Q: What is CNC machining?A: CNC machining (Computer Numerical Control machining) is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This technology controls a range of complex machinery, such as grinders, lathes, and milling machines, to create parts or products from various materials. CNC machining is highly precise, allowing for the production of complex shapes and detailed parts with consistent accuracy.

- Q: What kind of equipment do you have available?A: We have a wide range of high-precision CNC machining equipment, including CNC lathes, milling machines, grinders, and multi-axis machining centers. This allows us to handle various materials and produce complex, detailed parts with consistent accuracy. Our equipment is designed to meet the needs of industries such as automotive, aerospace, medical, and more.

- Q: What determines the cost of CNC machined parts?Material type, design complexity, production volume, machining time, finishing/tolerances, setup/tooling, and labor/overhead all influence CNC machining costs. Expensive materials, intricate designs, low-volume runs, extended machining times, additional finishing, and high overhead can increase costs, while higher production volumes may reduce per-unit costs.