Home / Industry Material Solutions

SOMI Manufacture

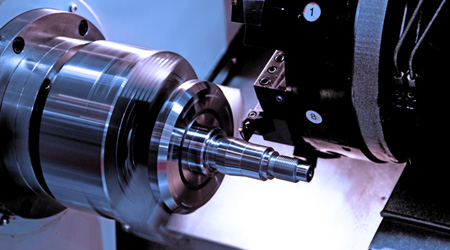

Metalworking Material Solutions

CNC Machining Materials

CNC machining and automated processes that produce precision, complex aluminum CNC machined parts with high dimensional tolerances.

Learn More

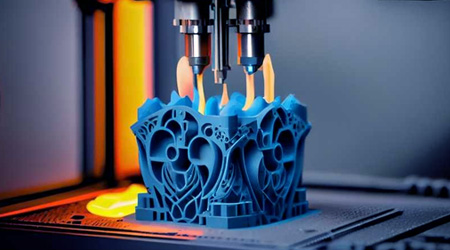

3D Printing Optional Materials

Laser cutting, plasma cutting, water jet cutting, and bending. Six materials including aluminum, stainless steel, and brass.

Learn More

Sheet Metal Fabrication Materials

Injection molding for plastic parts with intricate geometries, using a range of thermoplastics and thermosetting plastics.

Learn More

Injection Molding Materials

Additive technologies include metal 3D printing, SLA, SLS, FDM, and more. 30 plastic and metal materials in a range of finishes.

Learn More

Die Casting Materials

High-pressure die casting for aluminum, zinc, and magnesium alloys, ensuring excellent surface finish and stability.

Learn MoreFAQ

Frequently Asked Questions

If you have any further questions, please contact us. We look forward to working with you.

- Q: What materials are commonly used in die casting?The most commonly used materials in die casting are aluminum alloys, zinc alloys, magnesium alloys, and copper alloys. Each material has its unique properties and applications.

- Q: Can recycled materials be used in injection molding?Yes, recycled plastics can be used, but their properties may differ from virgin materials. It’s important to test and ensure they meet the necessary performance specifications.

- Q: How does moisture content affect injection molding materials?Excess moisture can lead to defects such as bubbles, poor surface finish, and reduced mechanical properties. Proper drying of hygroscopic materials is essential before processing.

- Q: How do I choose the right material for my injection molded part?Consider factors such as mechanical properties, thermal stability, environmental exposure, cost, and end-use requirements. Consulting with material suppliers and engineers can be beneficial.

- Q: How do I choose the right material for my project?Consider factors such as strength, weight, corrosion resistance, and cost when selecting a material. It's also important to account for the intended use and environmental conditions.

- Q: How do I choose the right material for my project?Consider factors such as the desired strength, flexibility, heat resistance, and environmental conditions. Additionally, think about the printing method and the capabilities of your 3D printer.

- Q: What materials are commonly used in sheet metal fabrication?Common materials include aluminum, stainless steel, carbon steel, and brass. Each material has its own unique properties, making them suitable for different applications.

- Q: Can I mix different materials in 3D printing?While it is possible to mix some materials, it requires careful consideration of their compatibility. Most printers can only handle one material at a time, so multi-material printing usually involves using a dual-extrusion setup.

- Q: What are the common materials used in sheet metal fabrication?A: Common materials used in sheet metal fabrication include stainless steel, aluminum alloys, carbon steel, galvanized steel, copper and copper alloys, magnesium alloys, and titanium alloys. Each material has unique properties and applications. For example, stainless steel offers excellent corrosion resistance and strength, making it suitable for food processing equipment and medical devices…

- Q: What are the most common types of 3D printing materials?The most common types include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol-Modified), TPU (Thermoplastic Polyurethane), and Nylon. Each material has its unique properties suitable for different applications.