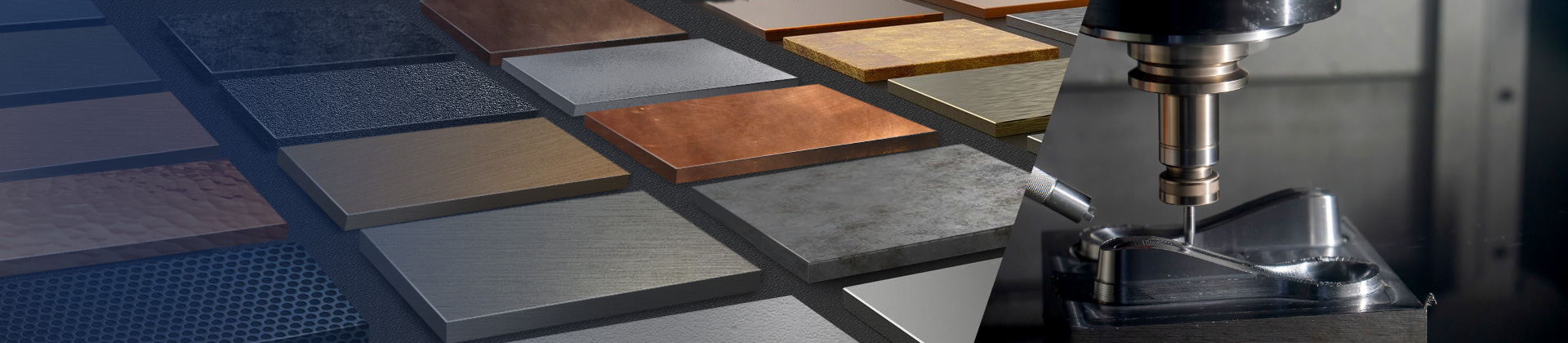

CNC Machining Materials

Materials

CNC Machining Optional Materials

- Aluminum

- Stainless steel

- Brass

- Copper

- Titanium

- Steel

- Polymer

Aluminum CNC

Aluminum 6061-T6 | 3.3211| 65028| AlMg1SiCu

Introduce:

Aluminium 3.3211/EN-AW6061 contains magnesium and silicon as its major alloying elements with trace amounts of copper.

Features:

Good strength-to-weight ratio, excellent machinability and natural corrosion resistance.

Aluminum 6060 | 3.3206 | AlMgSi

Introduce:

Aluminium 3.3206/EN-AW6060 has good resistance to corrosion, good weldability and very suitable for cold forming.

Features:

Heat treatable • Good weldability • Good corrosion resistance

Aluminum 6063 | EN AW-6063 | 62400| AlMg0,7Si

Introduce:

Aluminum 6063 has good mechanical properties and can be heat treated. Suitable for aerospace applications. Can be welded.

Features:

good mechanical properties and can be heat treated. Suitable for aerospace applications. Can be welded.

Aluminum 7075-T6 | 3.4365 | 76528 | AlZn5,5MgCu

Introduce:

Aluminum 7075-T6 (CNC) is an aerospace-grade material with excellent strength-to-weight ratio and strength and hardness comparable to steels.

Features:

High strength • Tough • Resistant to fatigue • Excellent machinability

Aluminum 6082 | 3.2315 | 64430| AlSi1MgMn

Introduce:

Aluminum 6082 (CNC) has very similar composition and properties to 6061, with slightly higher tensile strength. Compliant with British Standards.

Features:

Good thermal conductivity • High stress corrosion cracking resistance

Aluminium EN AW–2007 | 3.1645 | AlCuMgPb

Introduce:

Aluminium 3.1645 is a short chipped aluminum alloy containing between 4.0 – 5.0% copper. It is very suitable for high machining speeds.

Features:

Weldable • Strong • Can be anodised

Aluminum 7075-T651 | 3.4365 | 76528 | AlZn5.5MgCu

Introduce:

Aluminum 7075-T651(CNC) is the temper of Aluminum 7075, and to achieve this temper, the alloy is solution heat-treated, stress relieved, and then artificially aged.

Features:

High strength • Tough • Resistant to fatigue • Excellent machinability

Aluminum 6082-T651 | 3.2315 | 64430 | AlSi1MgMn

Introduce:

Aluminum 6082 (CNC) has very similar composition and properties to 6061, with slightly higher tensile strength. Compliant with British Standards.

Features:

Good thermal conductivity • High stress corrosion cracking resistance

Stainless Steel CNC

Stainless steel 304/304L | 1.4301/1.4307 |

Features:

Stainless steel 304L has excellent mechanical properties and good machinability. Resistant to most environmental and corrosive media.

Stainless steel 303 | 1.4305 | X8CrNiS18-9

Features:

Stainless steel 303 has excellent toughness, but lower corrosion resistance than 304. Ideal for high volumes, due to its excellent machinability.

Stainless steel 316/316L | 1.4401/1.4404 |

Features:

Stainless steel 316L has similar mechanical properties to 304, with higher corrosion and chemical resistance. Ideal for marine applications.

Stainless steel 301 | 1.4310 | X10CrNi18-8

Features:

Stainless steel 301 is corrosion resistant similar to Stainless steel 304.

Stainless steel 416 | 1.4005 | X12CrS13

Features:

Stainless steel 416 is magnetic and has a high machinability.

Stainless steel 430 | 1.4016 | X6Cr17

Features:

Stainless steel 430 is magnetic and corrosion resistant.

Stainless steel 420 | 1.4028 | X30Cr13

Features:

420 stainless steel has high strength and corrosion resistance. It is the hardest hardened of all stainless steels.

Stainless steel 440C | 1.4125 | X105CrMo17

Features:

Stainless steel 440C improves toughness and corrosion resistance due to the carbon and chromium content.

Brass CNC

Brass Cz121 | C38500 | 2.0401 | CuZn39Pb3

Features:

Brass Cz121/C360 (CNC) is a highly machinable alloy with good tensile strength and natural corrosion resistance. Ideal for parts that require low friction.

Brass C360 | 2.0375 | CuZn36Pb3 | 319 grade 2

Features:

Brass C360 (CNC) is highly machinable alloy with good tensile strength and natural corrosion resistance. Ideal for parts that require low friction.

Copper CNC

Copper 2.0065| E-Cu58Ms58

Features:

Copper 2.0065 has high electrical conductivity. Its good machinability makes it easy to shape into different forms.

Copper 2.0060| Cu-ETP

Features:

Copper 2.0060 has high conductivity and high corrosion resistance. It has a tensile strength of 360MPa. It has excellent machinability, Excellent solderability • Excellent formability

Titanium CNC

Titanium Grade 1 | 3.7025

Features:

Grade 1 titanium (CNC) is a commercial pure metal with excellent corrosion and impact resistance as well as good machinability and weldability.

Titanium Grade 2 | 3.7035

Features:

Titanium 3.7035 has excellent strength-to-weight ratio with good resistance to corrosion. Its thermal stresses are low.

Titanium Grade 5 | 3.7164 | Ti6Al4V

Features:

Grade 5 Stronger than Grade 2, equally corrosion-resistant, and excellent bio-compatibility.

Steel CNC

Alloy steel 1.7131 | 16MnCr5

Features:

Steel 1.7131 has high surface hardness and wear resistance with good machinability. It is ideal for machine components.

Alloy steel 4140 | 1.7225 | EN19 | 42CrMo4

Features:

Alloy steel 4140 has high strength, toughness, good hardenability and resistance to impact. It is widely used in the construction of machines

Mild steel 1045 | 1.0503 | C45 | EN8

Features:

Steel 1.0503 (C45) has low thermal conductivity and low ductility among wrought carbon steels. It has a high tensile strength of 630MPa.

Tool steel A3 - Annealed state

Features:

Tool steel A3 is an air-hardened general purpose tool steel with good toughness and excellent dimensional stability. Used for molding dies.

Tool steel H13 | 1.2344 | X40CrMoV5-1 - Annealed state

Features:

Tool steel H13 has an excellent combination of high toughness and fatigure resistance. It is the most common tool steel used in tooling applications.

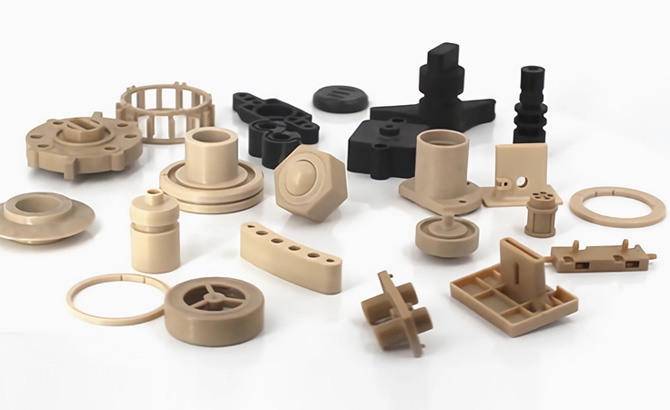

Polymer CNC

ABS(Acrylonitrile Butadiene Styrene)

Features:

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic material widely known for Tough • Strong • Resistant to impact and scratches.

Nylon 6

Features:

Nylon 6-PA6 - has excellent mechanical properties with high toughness and hardness. It absorbs moisture easily.

PTFE(Teflon)

Features:

PTFE (Teflon) is a highly slippery material with excellent resistance to extreme temperatures. It has outstanding frictional and insulating properties.

PC(Polycarbonate)

Features:

PC – Polycarbonate is a naturally transparent plastic with high strength and durability on impact. It is shatter resistant and heat resistant.

PEEK

(Polyetheretherketone)Features:

PEEK is an engineering thermoplastic with excellent mechanical and thermal properties. Can be used to replace metal parts. It is used in the production of components such as tubes, bearings, seals, valves, electric insulation and even medical implants.

FR4

Features:

FR4 is a class of glass fiber epoxy laminate that is flame retardant.

PET

Features:

PET is a tough plastic with excellent wear resistance and mechanical strength.

PVC

Features:

PVC is the third most used plastic, with good comprehensive mechanical properties, excellent chemical and weather resistance and good toughness.

POM(Delrin/Acetal)

Features:

POM is an easy resin for molding. It has a relatively high tensile strength as well as high resistance to wear, creep and warp.

PMMA(Acrylic)

Features:

Acrylic (PMMA) is the most common form of clear, moldable thermoplastic, often used in place of glass due to its higher resistance.

Garolite G-10

Features:

Garolite G-10 is a high pressure fiberglass laminate known for its high strength, low moisture absorption, and high electrical insulation.

HDPE

Features:

HDPE is a lightweight, high-strength thermoplastic suitable for outdoor applications. It is usually used for prototyping before injection molding.

FAQ

Frequently Asked Questions

- Q: What is the SOMI Partner Network?A:SOMI global network of premium manufacturing partners, With advanced production equipment, professional technical team. From prototyping to production, SOMI provide customers with high quality, high efficiency customized spare parts services, to provide project solutions for customers in different fields.

- Q: What does it cost to join the SOMI Partner Network?A: The SOMI Partner Network is free for partners to join. You really don't pay for anything. We don't have a trial period for the platform or membership fees and there are no hidden costs. Using the platform is absolutely free.

- Q: How to join SOMI Network?A: Submit the supplier application form and we will conduct a site and company profile review of your factory, and then verify that the product quality meets SOMI‘s quality standards through sample orders or small batch orders.

More Optional Materials for Custom Parts

Contact SOMI

Need Help?

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT or X_T).

If there is no drawing, please provide the product design requirements information, we will model and draw drawings for you tpo confirm.

Price updates in real-time as you change materials, lead times, and other order specifications.

We hope to discuss potential cooperation opportunities with you and ask you to provide quotation information for your project. Looking forward to your reply and working with you to promote the success of your project!

- *Name

- *Tel

- *Title

- *Content